Understanding and practicing the hierarchy of controls is especially valuable when two or more employers are collaborating in a shared work environment. Doing so can unleash tremendous value, lead to greater awareness around risk and controls, and help keep workforces safe.

In the context of the COVID-19 pandemic, how can the hierarchy of controls be leveraged for better performance in risk and safety? Consider a few common situations employers are facing right now:

- Returning to work

- Restarting operations following a shut-down, reconfiguring production lines and workcells

- Introducing new sanitation and hygiene protocols

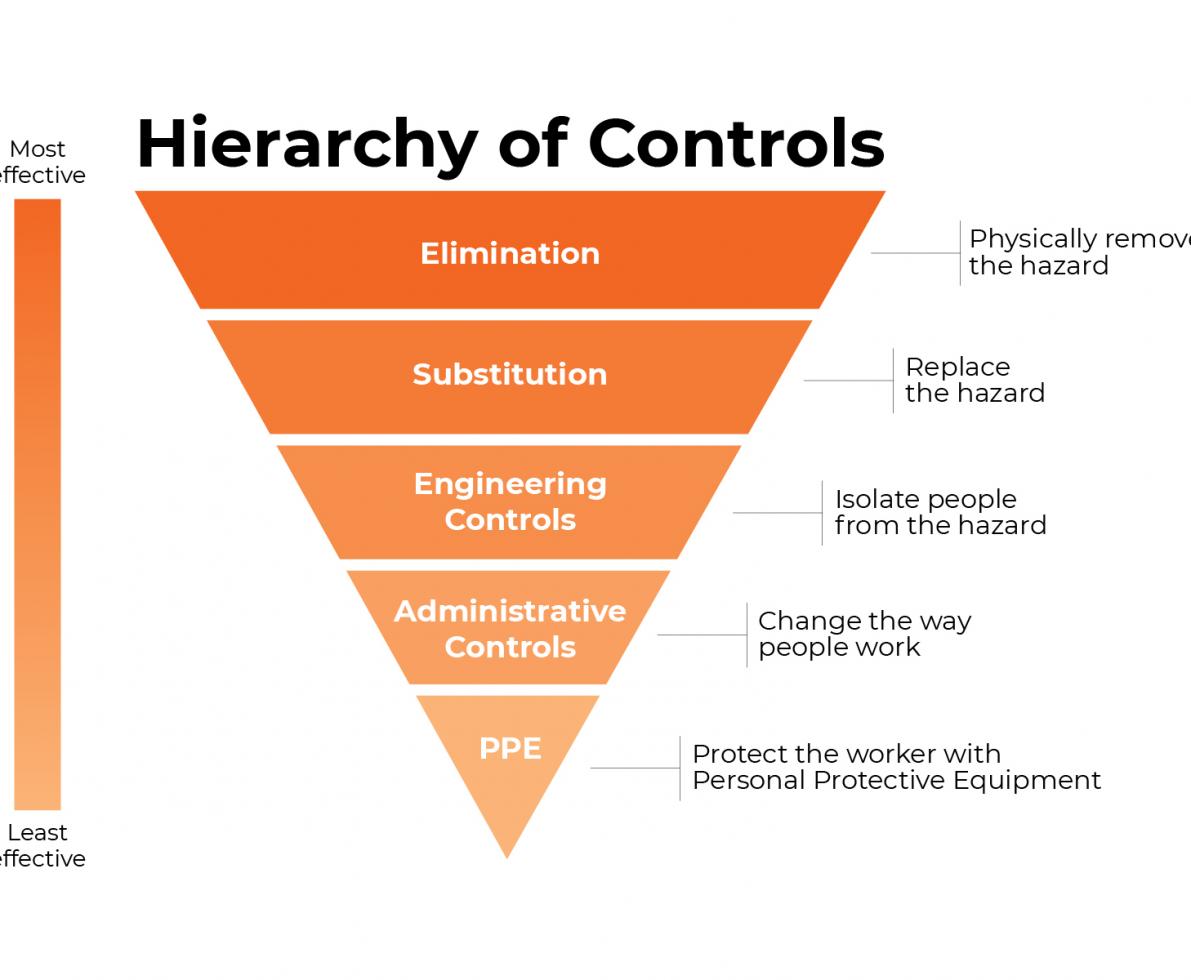

One possible approach is to “decompress” the work environment through workstation design, the use of guards or barriers, limiting seating areas, or even adjusting the speed of production to maximize distance. All of these options are worth considering at an engineering level. Of course, not all may be feasible for every work environment, but it is this pursuit of higher-level controls that delivers greater levels of reliability.

Risk always fluctuates during times of change. In fact, how we manage change directly correlates to the level of risk experienced by the workforce. Changing a production line to produce masks instead of curtains, for example, requires wide-ranging reconfiguration—everything from orientation and onboarding to training requirements and more.

For companies undergoing transformation, therefore, a few questions should be top of mind:

- What’s changing in our processes?

- How are changes and disruptions impacting the workforce?

- Are there any potential gaps, delays, new risks, and processes in our approach to our supply chain or vendor management?

- What are the limitations and challenges with our current safety equipment, such as the fit and function of PPE?

- Are front-line managers, as well as the workforce in general, fully informed on any changes? And do they know how to deal with new situations or risks?

- Can HR and staffing partners contribute in ways that will make my workplace safer?

Managing change in joint-employer environments is a terrific opportunity to drive safety improvements and better control for new and emerging risks. What’s more, it allows both parties to work collaboratively, which means identifying risk and solving problems can become yet another “new normal.” That should enable a stronger culture—and promote better safety outcomes.

* Source: CDC